We have multi-material molding technology, through which we can obtain molded items in: multi-color, multi-material, soft-touch.

We can take advantage of all major multi-component molding technologies:

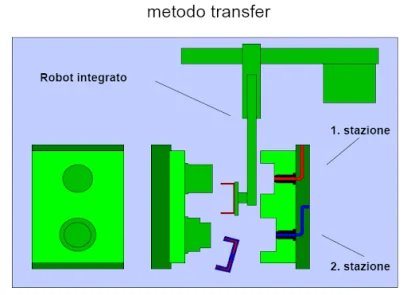

With such a solution, physical movement of the part between stations takes place, so as to reduce mold complexity and enable multi-material molding.

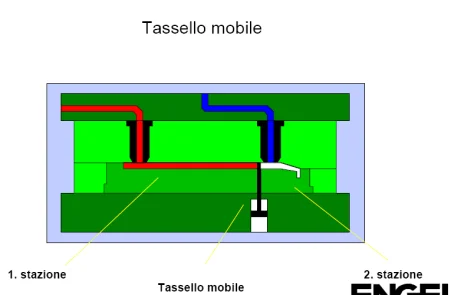

It is the simplest multi-material molding technology due to the presence of a hydraulically driven system inside the mold.

A special dowel (slide) allows the change of the filling chamber

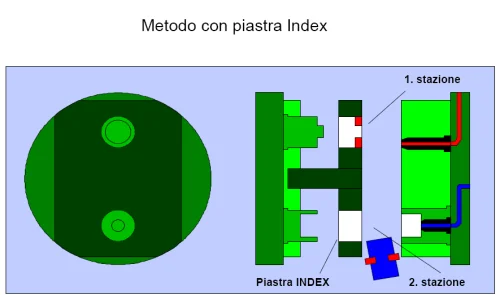

This is the most refined technology and involves the rotation of an intermediate plate between the moving and fixed parts of the mold; thanks to this mechanism, an integral change of the mold dies can be produced.

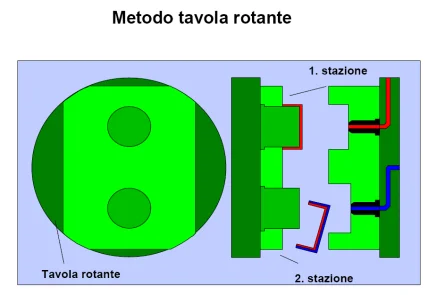

This is a system whereby a half mold can rotate up to 180° to change the male-female coupling.

Cimplasta also has three-component technology, where the mold rotation occurs at 120° so that the three resins can be injected separately.

In many applications the technologies are then merged (example rotary table and movable dowel).

Request Information

We and selected third parties use cookies or similar technologies for technical purposes and, with your consent,

also for other purposes as specified in the .

If you close this banner with a tick or click on "Decline", only technical cookies will be used. If you want to select the

cookies to be installed, click on 'Customise'. If you prefer, you can consent to the use of all cookies, including

cookies other than technical cookies, by clicking on "Accept all". You can change your choice at any time.